Working with the right tools is the first requirement to obtain the desired results. As a matter of fact, choosing the right pipe bung is the first step for your pipeline maintenance and/or testing project.

Therefore, first, you should calculate the back pressure that the pipe bung must withstand.

How to calculate the back pressure?

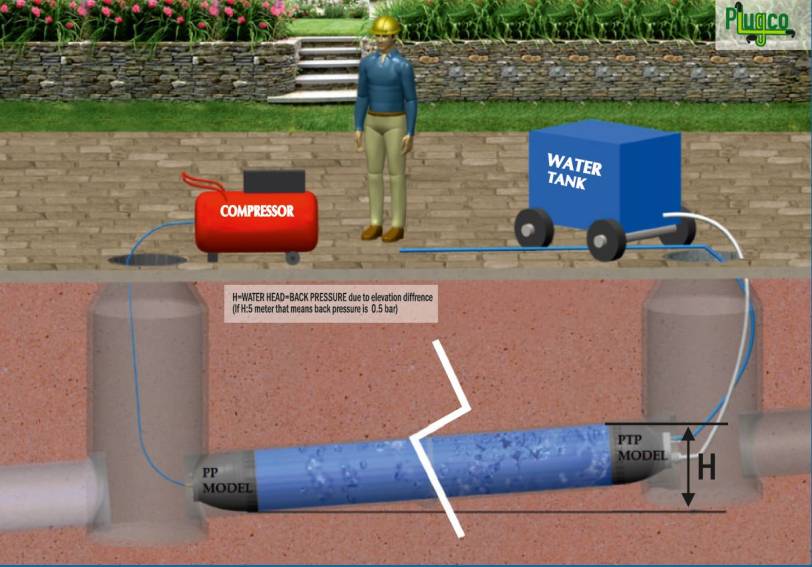

Back pressure is the elevation difference between the upstream and downstream ends of the test line; or, in other terms, the height of the water column behind the pipe bung. (Ten meters water column equals 1 bar back pressure.) The surface area and the shape of the water column are not important, hence only the height of the water column needs to be considered.

- Measure the inner diameter D (mm) of the pipeline to be sealed by the pipe bung.

- Calculate the surface area S (mm2) of the pipeline cross section as the following equation:S: π D2/4 (mm2)

Where π: 3,1416 - Calculate the total force that pipe plug must withstand as the following equation:F= PxSx10 (N)

Where, S-Surface Area (mm2)

P-Back Pressure (Bar)

D-Inner Diameter of The Pipe (mm)

F-Total Force (Newtons)

As the second step, determine the temperature that the expandable pipe plug will experience, and the fluids it will contact when in use. The acceptable temperature range is specified in the PlugCo datasheet. If the pipe bung is used outside of the lowest specified temperature, it may stiffen resulting in incomplete contact with the pipeline surface and may dislodge when back pressure is applied. Also, high temperature application may cause losing the elasticity.

Then, you are ready to select the proper pipe bung and related equipment for the application. Before using, measure the inner diameter of the pipe. Lastly, make sure that the pipeline diameter is within the range specified for the pipe bung in the technical information tag on

the product.

Relatedly, in order to find out what you need to do next after choosing the right material, check our article here about Avoiding the Misuse of Expandable Pipe Plugs.