It is very serious, risky and unsafe to be the person in charge of the installation of plugs, replacement of pipes, or any kind of infrastructural applications. Therefore, every little step should be taken carefully before starting the application.

In this article, we will take the testing of infrastructural pipes as an example. The inflatable plugs are used either to stop the flow of a liquid or gas into the pipe or to test the pipe for leaks. For these tests to be successful, the plugs must withstand the back pressure applied by the fluid inside the pipe.

Usually, all manufacturers of this type of plugs inform their customers or end-users about the back pressure, or the height of water, that the plug can withstand. But unfortunately, this back pressure is always given for a specific type of pipes, as clean & dry concrete pipe or ductile iron pipe… So, when the plug is used in different pipe or for a different usage, the plug will not be able to withstand the same indicated back pressure. This will cause the plug to slide, which may lead to bursting, resulting in financial loss, serious injury or even death.

What is a SmartPlug?

Before starting the use of a plug, it is necessary to know the actual/exact back pressure of the pipe plug in the line that may be filled with debris or foreign materials such as grass, oil, mold, or others; which reduce the back pressure holding capacity inside the pipeline for pipe plug. At this point, PlugCo’s patented Smart Plug product will be the right solution to solve this problem by providing the real status of back pressure of the pipe.

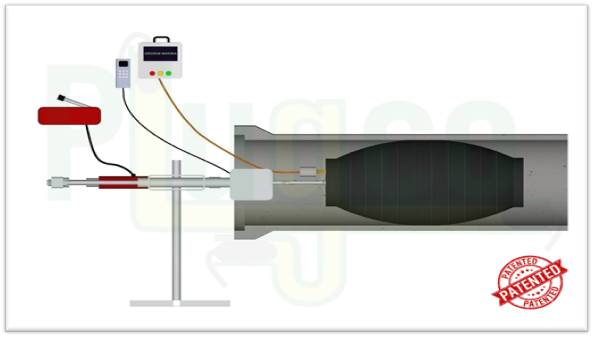

As shown in the picture below, SmartPlug, is a logical measurement device equipped of a Pressure Monitoring and Alarm System, a Loading Mechanism and a Software to Calculate the Back Pressure.

How to use a SmartPlug?

Once the plug is placed in the pipe, the loading mechanism ensures that it is well centered. The user then starts to inflate the plug by the compressor, as normal, to the optimum inflation pressure according to the technical specifications. The loading mechanism, pulls the plug backwards to see at what load it will move. After continuously pulling the plug for several times, the user should note all the force values acquired.

Based on the values obtained in the previous steps, all required data can be submitted to the back pressure calculation Software, which is Available in PlugCo Website, to get the exact back pressure of the pipe plug.

To accomplish all the work, PlugCo has also programmed a Monitoring System, that will be connected to the plug, to help the user to control and monitor the pressure; So, after obtaining the back pressure that the plug can withstand, it is now enough to set it on the Pressure Monitoring and Alarm System, which is also manufactured by PlugCo. This System will display the current back pressure at all times and inform the user with a green LED if everything is OK and warns with a buzzer and a red LED if there is a dangerous situation. This process will help to avoid the damages that may occur during the applications.