Inflatable Pipe Stopper is mainly for temporarily blocking and stopping the flow in the pipe lines. These flows can be sewer, storm water, gas or oil. Also, they can be used for gravity pipelines leakage testing. These pipe stoppers are generally inflatable products. Pipe Stoppers called many different names in the market such as inflatable pipe plugs, pipe balloons, pipe blockers, pneumatic plugs and rubber plugs. Pipe Stoppers are made by reinforced rubber. They are inflated by air. Each Pipe Stopper has own sizes and features such as diameter, inflation pressure and back pressure. If we want to select the suitable Pipe Stopper we have to know information about its inflation pressure and back pressure. Selection of suitable Pipe Stoppers depends on its features.

Inflation pressure and back pressure are important parameters for selection. Back pressure means that the height of the water column behind the pipe stopper. In the other word the pressure is hold by the pipe plug. If Pipe Stopper cannot hold the water on the behind, it will slide in the pipe and exit the pipe. So, Pipe Stopper under pressure can be dangerous for the operators. In the other hand when Pipe Stopper inflating by air it creates pressure on the contact surface. If pressure exceed the maximum inflation pressure of Pipe Stopper, it will burst. That may cause death. So, over pressure/compressed air have to discharged. It can be done by using Pressure Relief Valve.

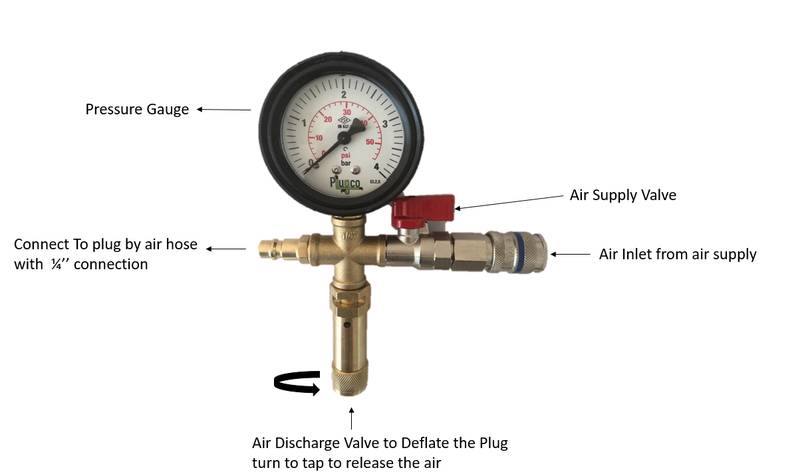

Pressure Relief Valve (PRV) can discharge the over pressure, if pressure of the pipe stopper exceeds the maximum inflation pressure. Also PRV can keep the set pressure. It can be set up at the desired pressure. If the more pressure tries to enter in the pipe stopper, the spring in the PRV will be compressed and the pin in the PRV will be move up. And, pressure will be kept on the set pressure by the PRV. After finish the all procedure, pressure can be discharged by the PRV using air discharge valve.