City/Country: Dubai / United Arab Emirates

Contractor: Jamal Al Sherouq Tech. Cont.

Date: April 2021

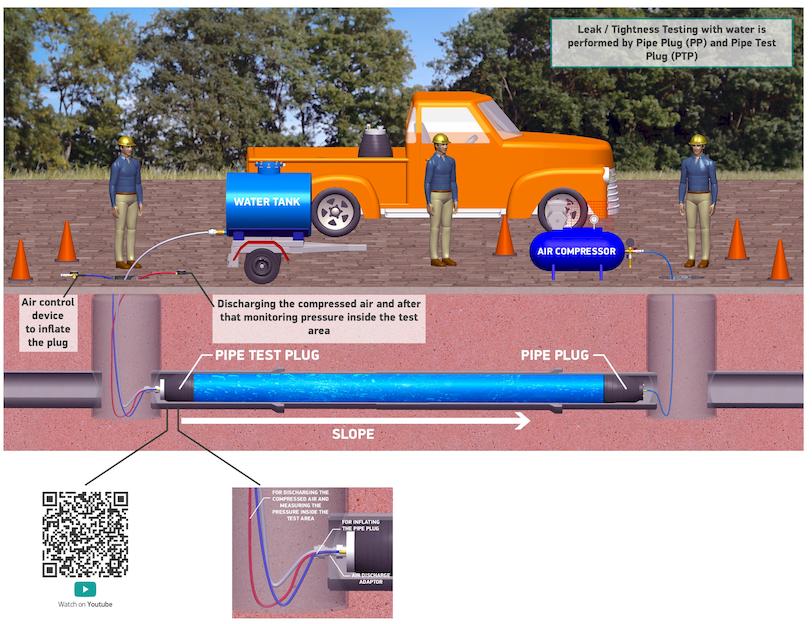

Service: Training & Supervision service for 1200mm Dia. for water leakage test.

PlugCo’s Engineer arrived at the project site in Dubai on April 6th to make water leakage test and train technicians for the ongoing pipe project.

IMPLEMENTATION: Their application is to make water leakage test for a new pipeline.

Firstly, the subcontractor contacted PlugCo to discuss details to complete the water leakage test for a new 1200mm dia. pipeline.

There is a new GRP pipe line in this project. The contractor needs to make leakage test to complete the project after the pipe is installed. It is a long pipeline and there are too many joint points because they used 12-meter pipes and joint them together. The consultant accepts only the water test. So, we recommended them to use PP model plugs and fill the water from manhole. However, consultant did not accept to fill water from manhole. Consultant insisted on filling the water in the line through the pipe test plug. They would like to make the test with less water so they did not want to fill it from manhole. So, we recommended our PTP model plugs. PTP model plugs have a bypass connection that allowed them to fill water easily from the bypass line.

PlugCo offers the best cost-effective solutions to the client.

In this project, there was elevation difference of 6-8 meters for each test area. We considered the height difference between upstream and downstream as 10 meters to be in safe side. So, PlugCo provided PTP model pipe test plug that can withstand 1 bar back pressure.

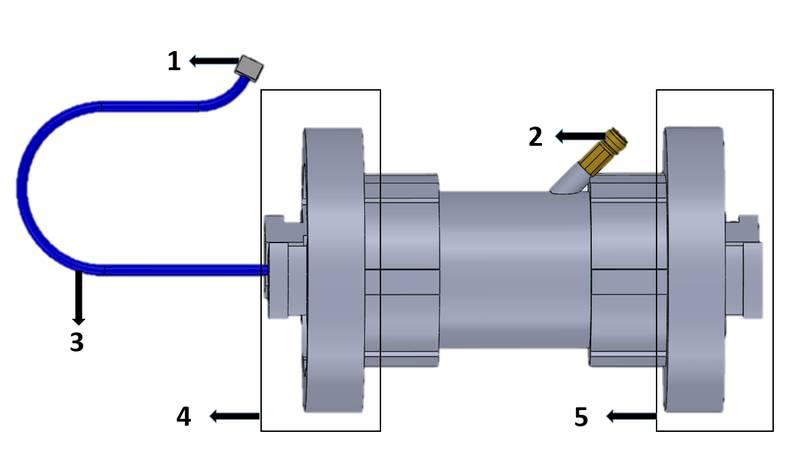

PlugCo dispatched the goods to Dubai end of March. PlugCo shipped the PTP6001200 model and all the necessary accessories for water test as well. The most important accessory is the “Air Discharge Adaptor” to make the water test; To close the line with Pipe test plugs and add water into the test area, they should discharge the compressed air from the area to make the test correctly. The unique option to perform it is to use the Air Discharge Adaptor (ADA). So, they used ADA on test plugs and they discharged the air from the test area successfully.

How to Use the Air Discharge Adaptor?

- Float-Discharging the compressed air from inside of the pipeline to the outside.

- Quick Coupling- To be connected to the hose to discharge the air to the outside. Once the air is discharged, the water flows out of the end of the hose. A pressure gauge can be connected to the end of the hose to monitor the water pressure. This end can also be used for pressurizing the pipeline.

- Air Hose to discharge the compressed air.

- Connection to Pipe Plug.

- Connection for Water Hose to fill water to pipeline.

- Air Discharge Adaptor is connected to the Pipe Test Plug from the left (#4) and is connected to the water hose from the right (#5), as illustrated in the below picture.

- The air hose used for discharging is connected to the quick coupling and the pressure gauge is connected to the air hose.

- The pipe line is filled with water by the water hose.

- During the water filling, the compressed air in the pipe line is discharged by the float.

- The compressed air in the pipe will be discharged through the air hose.

Then, PlugCo gave its own suggestions on how can they centralize the plug and brace it against sliding.

PlugCo has a new accessory that called centralizer which is recommended to be used especially for big size plugs. We gave them more information about centralizing and we informed them that bracing is mandatory to prevent any sliding while using pipe plugs. And then, we saw the bracing and confirmed that is suitable to start testing.

In the meantime, you can read our article that was written about the consequences of not centralizing and supporting the plugs. https://www.plugco.net/why-pipe-plug-is-sliding

As a result, PlugCo has provided supervision, training service and attended the client’s project to help them with their project.