When the users ask us for plugs, our team basically needs to know the answers to a few questions in order to determine what type of plug would be the best option.

- What is the size of the pipe?

- What is the material of the pipeline?

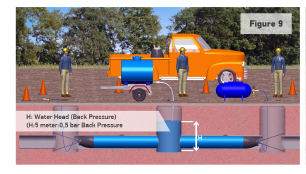

- What is the back pressure?

- How long is the plug going to be in place?

- And what is the media inside the line that has to be considered as well.

May the most critical answer that affects the whole choice of the suitable plug is the back pressure, when the back pressure is high our standard inflatable pipe plugs will not work.

In these cases, we offer high-pressure pipe plugs for our customers to be used safely in their applications.

These plugs are usually used in water line systems or industrial lines to seal the pipes. It is also used for leak tests, including air leak tests and water leak tests.

The applications of the high-pressure plugs

One of the most popular usages for high-pressure pipe plugs is hydrostatic testing, which is essential in numerous industries to ensure the safe and effective operation of pressure pipelines, gas cylinders, boilers, nuclear process lines, and fuel tanks. The test is used to check these vessels for failures such as cracks, leaks, and welding defects.

During this process, the ends of the pipeline are blocked, filled with liquid, and pressurized to predetermined test pressure.

The standard range of Our high-pressure pipe plugs withstands and resists a back pressure of 6 bar with a usable size ranging from 100 mm to 2000 mm. Customized plugs are made for cases where the back pressure is greater than 6 bars.

As safety is our first priority, delivering the most economical solution to our customers also takes our attention. It is noteworthy that our high-pressure pipe plugs are multi-sized, which means that one plug can cover multiple pipes in the same range.

PlugCo offers complete service for their customers, from manufacturing the plugs to providing their customers with technical datasheets and instruction manuals. And sometimes providing training to their clients if needed. This full service guarantees that the plug applications are made safely and successfully.