The European Standard EN1610 requires two types of leak test methods for gravity pipelines. First one is “Water Filling through Manhole” and the second one is “Water Filling through Plug”. In our article, you will find the details of Leak Test Procedure as per EN1610 by “Water Filling through Manhole” method.

How to do Leak Test as per EN1610?

The necessary equipment for the Leak Test as per EN1610 is as follows:

- 2 Pieces of PP Model Pipe Plugs

- 10 Meters Air Hose

- 1 Air Control Device

- 1 Air Supply

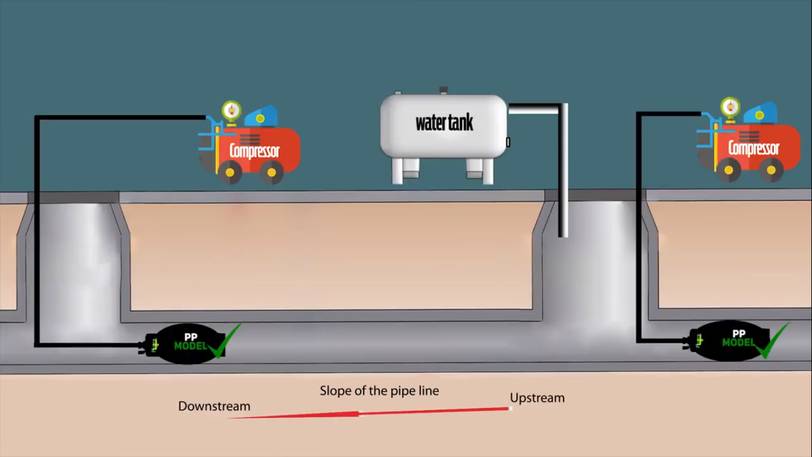

After placing the pipe plugs properly in accordance with the slope of the pipeline (as shown below) inflate the pipe plugs up to the maximum allowable inflation pressure.

Fill the test section with water up to 5 meters through the manhole and monitor the water level. Height of 5 meters is measured as of from the invert of the pipeline. Because 5-meter water head is equal to 0,5 bar (50 kPa).

For the pipeline, excluding manholes and inspection chambers, the test pressure shall be the pressure equivalent to or resulting from filling the test section up to the ground level of the downstream or upstream manhole, as appropriate, with a maximum pressure of 50 kPa and a minimum pressure of 10 kPa measured at the invert of the pipe.

Wait for half an hour in this position and meanwhile make the necessary recordings. The variation of volume of water during the test shall be measured with an accuracy of 0,1l and recorded with the head of water at the required test pressure.

And then, deflate and remove the pipe plugs as per the user manual.

The test requirement is satisfied if the variation of volume of water during the test is not greater than:

- 0,15 l/m2 during 30 minutes for pipelines

- 0,20 l/m2 during 30 minutes for pipelines including manholes

- 0,40 l/m2 during 30 minutes for manholes and inspection chambers

*Note: m2 refers to the wetted internal surface.

As an experienced pipeline leak test implementer, PlugCo offers further assistance at the email address sales@plugco.net and at mobile +90 533 545 81 97.