Joint Tester are testing joint parts of two pipes. Joint tester provides advantages such as less water consumption and fast testing time of the joints. Foldable Joint Testers are required when the pipe size bigger than the manhole access size. It is collapsible Joint Tester for No-dig solutions. The contractors are preferring to have foldable Joint tester to test the pipeline because usually the manhole size around 600mm and it is not possible to entering the single part joint tester.

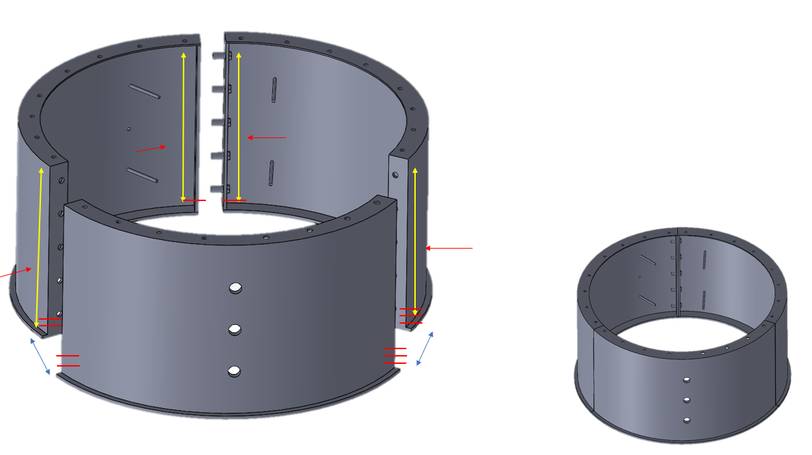

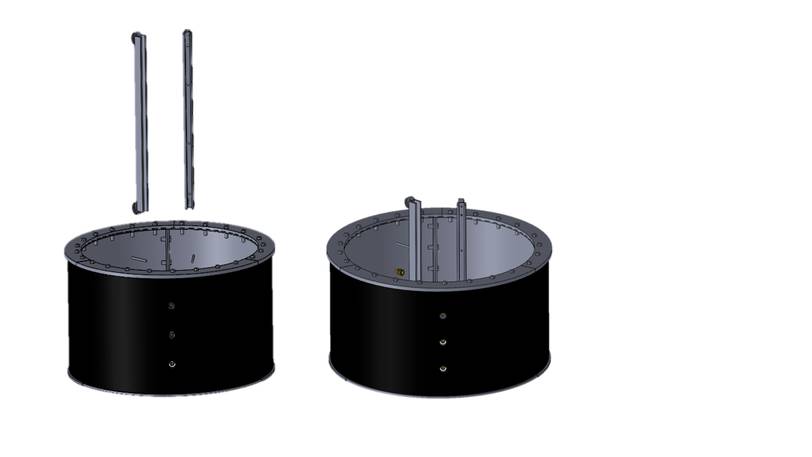

FOLDABLE JOINT TESTER-3 is consist of 3 parts and 2 wheels. The first part is including 3 holes for quick coupling. One of them for discharging the air from test area and after air finished to connect the pressure gauge to monitor the test pressure. Other two for inflation for the bladders. The second part is including 2 shafts for wheels and 1 hole for quick coupling to supply water to test area. The third part is including just 2 shafts.

ASSEMBLY OF JOINT TESTER-3

1. Firstly, set the pieces that the red lines on the pieces match each other and connect the joint points by the nuts.

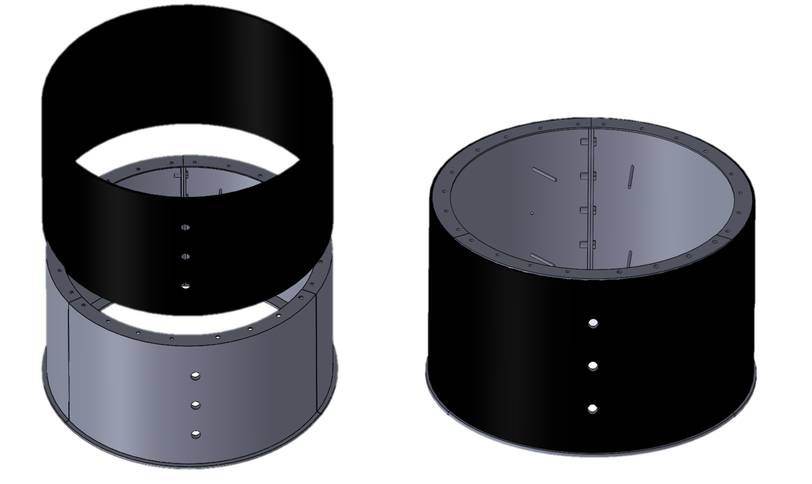

2. Wear the rubber part to the joint tester. You may use soapy water to insert the rubber bladder easily.

3. Connect the quick coupling to the related part. Total, 4 Quick Couplings must be connected to the related part.

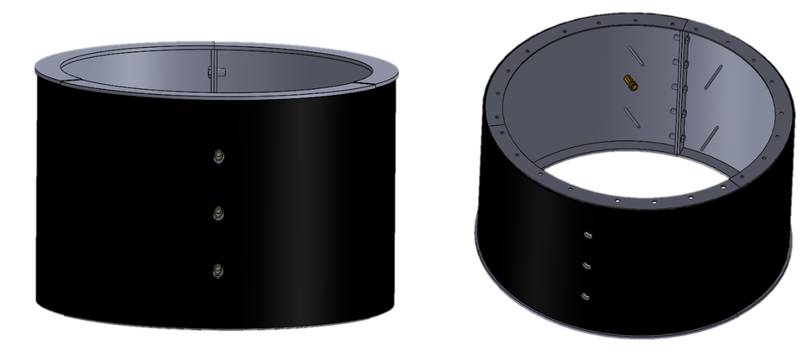

4. Connect the plates to the top surface of the joint tester.

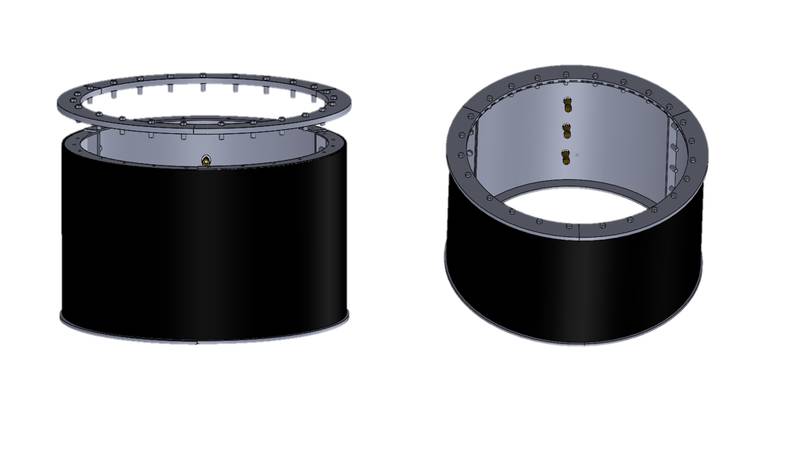

5. Lastly, connect the wheels to the related parts and adjustable level of the joint tester in the pipe by turning of the nuts. The joint tester to be centralize from that point by turning nuts.

Please visit our website to get more information about operation of the Joint tester. You may download operational manual from the pdf here. Also, you can watch the joint tester operation video from the video here.